Page 1 of 1

slugging a frame

Posted: Sat Nov 09, 2013 10:45 am

by krymis

Re: slugging a frame

Posted: Sat Nov 09, 2013 4:21 pm

by railroad bob

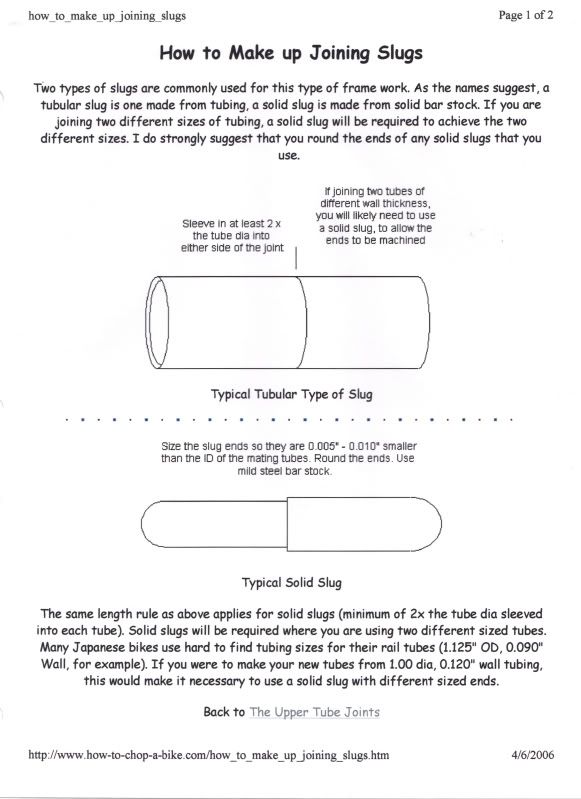

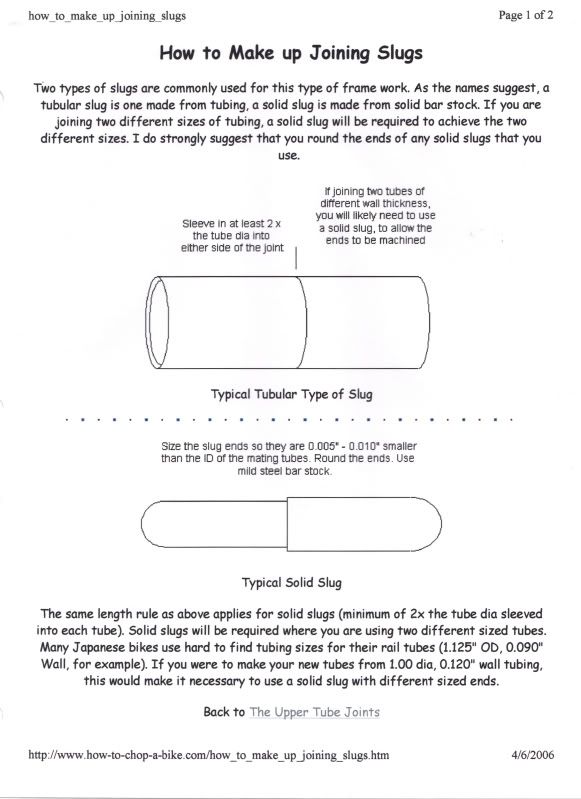

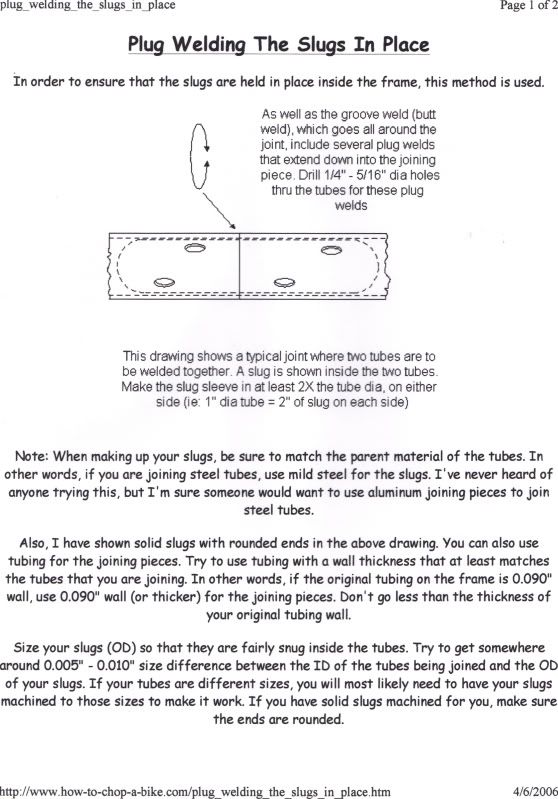

Nice videos, especially liked the tip about rounding the ends of the solid slugs.

I hadn't thought of it, but if a sharp edge is left on the end of a slug, it does become

a stress riser when the frame flexes. The sharp edge is in contact with the inner wall of the original frame tube.

Good stuff...

Re: slugging a frame

Posted: Sat Nov 09, 2013 6:27 pm

by curt

I never rounded the ends before sounds loke a good idea I always put a 45 on the ends . I always try to use solid the same od as the tube and machine it down I also leave a 1/4 inch in the center of the slug and machine a 45 on both sides to help weld the tube to the slug so I can grind the weld down smooth with the od of the tube without sacrificeing weld strength

- 074.jpg (118.08 KiB) Viewed 11710 times

and I know this was before I did the 45 on the outside ends

Re: slugging a frame

Posted: Sun Nov 10, 2013 4:27 pm

by hansgoudzwaard

Thanks for sharing and taking the time to post this.

Re: slugging a frame

Posted: Tue Nov 12, 2013 8:22 pm

by yona

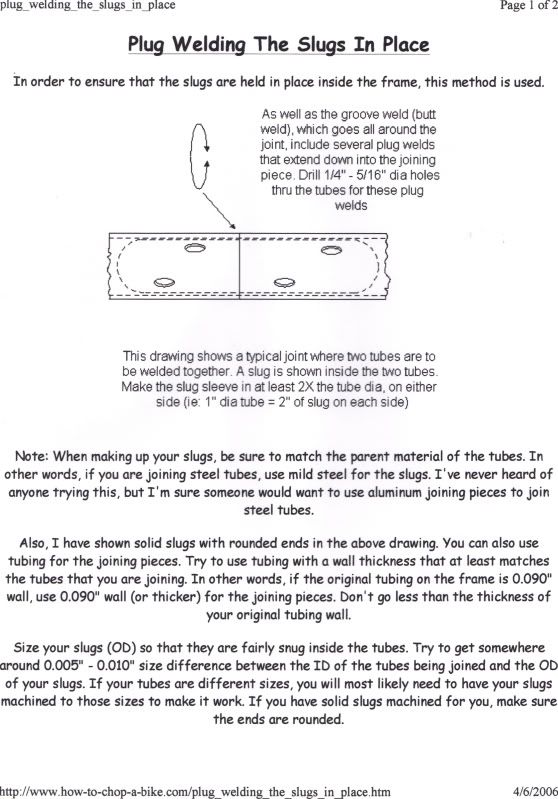

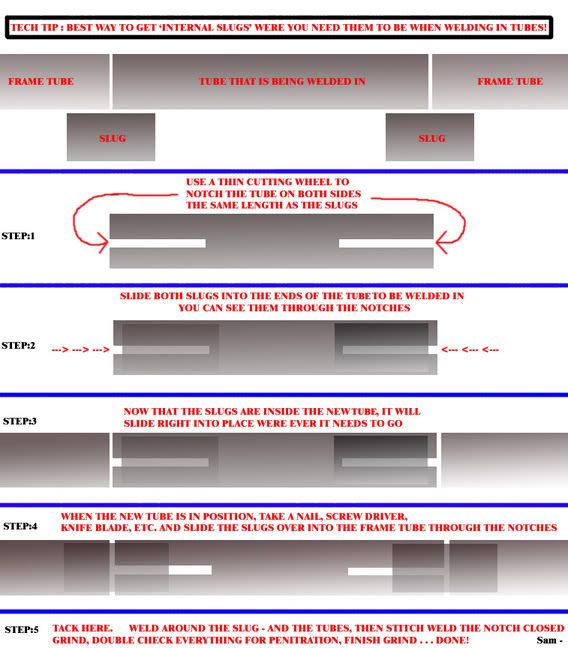

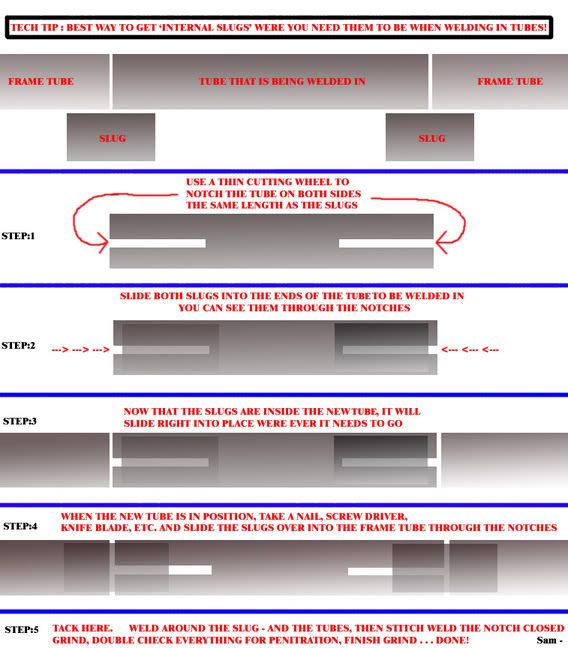

I have used heavy walled tube to make slugs and cut the inside down so that the tubing of the slug is the same... that way the same settings on the welder can be the same..... I 45 the joint, but I use slots on the frame tube for two reasons.... It make the frame tube "give a little" to get the slugs in and it gives you more weld area on the slug. I drill four holes and then mark the side of the hole to the end of open tube, cutting with a cut off blade. Drilling the hole doesn't leave a sharp end that might split from flexing. the same way you stop a split in flatbar or sheet metal. Haven't had a frame break in 45 years, but what do I know , I have no formal schoolin ! ... ; )

Re: slugging a frame

Posted: Wed Nov 13, 2013 1:41 am

by hansgoudzwaard

yona wrote: I drill four holes and then mark the side of the hole to the end of open tube, cutting with a cut off blade. Drilling the hole doesn't leave a sharp end that might split from flexing. the same way you stop a split in flatbar or sheet metal. Haven't had a frame break in 45 years, but what do I know , I have no formal schoolin ! ... ; )

That's good advice. If that works on sheet metal, for sure it works here.

yona wrote: Haven't had a frame break in 45 years, ... ; )

Most of us here haven't been around that long........

Re: slugging a frame

Posted: Tue Mar 11, 2014 1:13 pm

by TattooLeeRoy

They call it a stop drill when you put it at the end of a crack. The stress risers that cause the cracks to grow get dissipated when it gets to the hole. It just has to be a big enough hole.

Re: slugging a frame

Posted: Fri Dec 05, 2014 5:40 pm

by Maz

Good and accurate descriptions dude, I will sometimes use tubing machined to match the thickness of the original frame, and then bevel the inside edges so I can safely run wiring through at a later stage of the build

Maz

Re: slugging a frame

Posted: Fri Dec 05, 2014 7:42 pm

by yona

Tat .... I drill the holes and cut slits to the hole that makes 4 slots with no stress risers . Tube is then beveled and welded to the joint, then welded all the way around, after tacks are made at the slots to stop pulling .... might not have been clear ... been a while since this post ... ; ))

Re: slugging a frame

Posted: Sat Dec 06, 2014 12:22 am

by railroad bob

Maz wrote:Good and accurate descriptions dude, I will sometimes use tubing machined to match the thickness of the original frame, and then bevel the inside edges so I can safely run wiring through at a later stage of the build

Maz

good tip, no sharp edges to cut the insulator, or hang up while pulling...