Page 1 of 2

Tank Mods & Welding

Posted: Thu Mar 29, 2012 11:12 am

by rudog

Indecision is a bitch! I've been stalled for the past few days trying to mount my tank. It's a paughco tank with one mount at each end of the tunnel. Not my idea of a good idea. The wels are also full of pinholes and the grinds went thru the welds in some places.

My original idea was to cut the weld, narrow the tunnel and install hidden mounts for the front. I can't see any other way to do it, so, I'm going to bite the bullet and start cutting. Prolly start welding soon. Comments are requested.

- MockUp45.JPG (24.95 KiB) Viewed 6930 times

I'll prolly cut or burn a gap to build a goodsized bead. I'm a gap welding fool. I can do this by adding filler to the weld and blending to the sheet metal. It'll be slow, but I can alter between the 4 corners and work inward. This will allow me to file a nice corner radius. Warping is my concern.

I'm still deciding wether to make billet mounts or a die to draw formed mnts. Billet is easier to make. Drawn is easier to work with.

With the top of the tank @36" off the ground, no-one will ever see the tunnel or mnt unless they're looking for it. If it works it should look really clean and sharp with just enough radius to hold paint.

Re: Tank Mods & Welding

Posted: Thu Mar 29, 2012 12:04 pm

by Jeff L

Hidden mounts are the way to go.Would look real nice with the low frame if you deepened the tunnel.

Re: Tank Mods & Welding

Posted: Thu Mar 29, 2012 12:46 pm

by rudog

Just got the tunnel out. The welds were better than they looked.

With the lip gone, I can prolly drop the tank 1/4". Doesn't seem worth it. If I make a new tunnel, I could go 3/4". I may thro the motor back in to see where it sets.

Re: Tank Mods & Welding

Posted: Thu Mar 29, 2012 4:14 pm

by Maxthegardener

Iam going to use the thinnest wire I can find to run on my mig .5, was wondering if you could put the mounting blts though a bung vertical like, into the botton of the tank?

Re: Tank Mods & Welding

Posted: Thu Mar 29, 2012 5:26 pm

by rudog

Maxthegardener wrote:Iam going to use the thinnest wire I can find to run on my mig .5, was wondering if you could put the mounting blts though a bung vertical like, into the botton of the tank?

Yes. But...also recessed so they are not visible with casual observation.

- standard-features.jpg (33.53 KiB) Viewed 6916 times

I'll be tiggin' it. After looking at this, I'll need 1 1/8" recess. Too much for me to draw. I'll make the mounts from billet. I'll weld a well nut and try to keep my wall thicknes less than 1/8"

Re: Tank Mods & Welding

Posted: Thu Mar 29, 2012 5:54 pm

by Maxthegardener

mmyeah I meant throught the backbone..straight up into the tank?

Re: Tank Mods & Welding

Posted: Thu Mar 29, 2012 7:24 pm

by rudog

Gotcha now! I was worried for a moment.

The tank had 2 mnts along the backbone already. Your idea is really nice. My worry is that the tank will rock side to side. Of coarse, if you could weld some flats inside the tunnel, that would prevent the rock.

SHIT!!! Now I'm at a standstill again. I gotta work this thru.

Re: Tank Mods & Welding

Posted: Thu Mar 29, 2012 7:26 pm

by Maxthegardener

just went a bit occ on ya..

Re: Tank Mods & Welding

Posted: Thu Mar 29, 2012 7:35 pm

by rudog

I can't do it anyway. With the backbone so low, I wont have room. Plus with all the stress I'll have on my seatpost. I'ld rather not start drilling holes in it or the backbone.

Re: Tank Mods & Welding

Posted: Thu Mar 29, 2012 10:23 pm

by rakeNtrail

Maxthegardener wrote:Iam going to use the thinnest wire I can find to run on my mig .5, was wondering if you could put the mounting blts though a bung vertical like, into the botton of the tank?

When mig welding sheet metal switching from 75% Ar-25%CO2 to 92% Ar-8%CO2

The decrease in CO2 decreases penetration and heat build up. You'll be able to weld long runs on sheet metal without blow threw and fall out.

92-8 is available at most welding suppliers.

Re: Tank Mods & Welding

Posted: Thu Mar 29, 2012 11:52 pm

by rudog

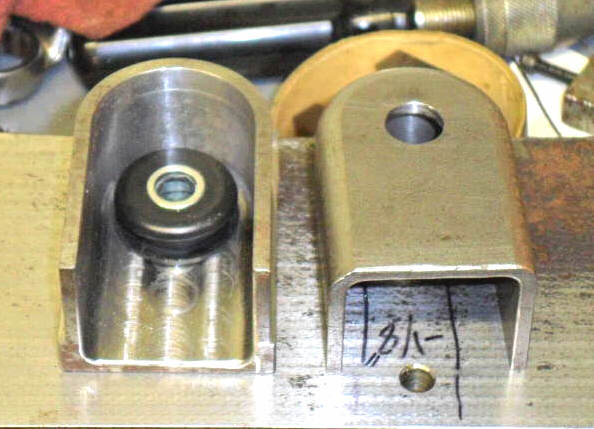

This is the last thing I'll do for today. It worked pretty sweet. Tomorrow the well nuts and welding.

- MockUp46.JPG (43.9 KiB) Viewed 6896 times

In nomine Patris et Filii et Spiritus Sancti

Posted: Sat Mar 31, 2012 10:35 pm

by rudog

- MockUp47.JPG (32.16 KiB) Viewed 6879 times

I started gap welding where I had to and discovered by accident that leaving a 1/16" lip I could weld without filler. Sweet!

Re: Tank Mods & Welding

Posted: Sat Mar 31, 2012 11:45 pm

by Maxthegardener

Bless you my son...that looks neat..

Re: Tank Mods & Welding

Posted: Sun Apr 01, 2012 1:17 am

by rudog

Thanx, Max. I'm quite pleased.

Re: Tank Mods & Welding

Posted: Sun Apr 01, 2012 9:33 am

by Jeff L

Nice job...looks good man.