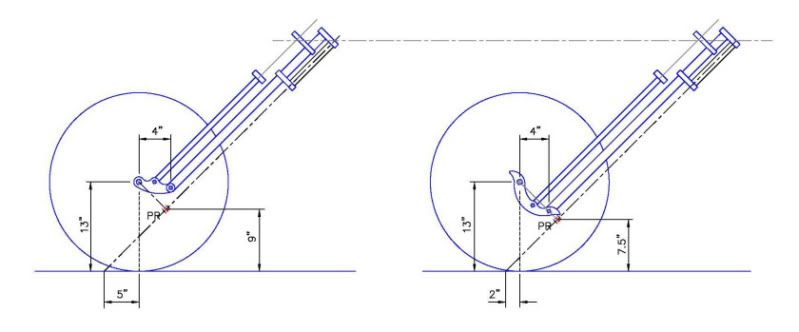

the 90* angle rule: this rule was set up to dictate the proper measuring and assembly of the springer rockers. First and foremost do not have any weight on the frontend. I block the front of bike frame with 2x4 and shimming stock. I set the front of the frame.75 to 1" above the final position of the weighted frame(containing motor trans and rider). For lighter riders i set closer to .75" for riders 200# or more i go a full 1". This rule dictates the position of the rear(rigid leg) rocker attachment hole. that in turn will tell you where to place your spring leg attachment hole.

rule 1: place the blade (the long end) of a carpenter's square along the centerline of the steering axis. If not using raked trees or raked cups you can simplify this and use the centerline of the rigid leg of the springer. Align the tongue (the shorter leg) of the carpenter's square with the centerline of the axle. If using the centerline of the rigid leg, the point of the square will be where you should place your rigid leg rocker attachment hole. With this hole made you can in turn make the spring leg rocker attachment hole by setting level at horizontal zero along the centerline of the rigid leg rocker attachment hole. follow the horizontal zero forward to the intersection of the centerline of the spring leg. the point of intersection is where the spring leg rocker attachment hole should be placed. Once the frame is taken off the cribbing and the weight is applied to the frame, the rockers will preload the spring leg and naturally set the rocker attachment holes 10-20* of horizontal zero.

rule 2. expanding upon rule one, if the 90* rule can not be utilized in a flowing rocker design you may have to go to the horizontal zero rule. and that is: if a 90* can not be acheived then set a horizontal zero line that intersects centerline of axle, centerline of spring leg, and centerline of rigid leg. this will place the unweighted rocker attachment hole in horizontal alignment with the axle. there by getting the rocker holes to be at a 10-20* off of horizontal zero along the centerline of the rigid leg attachment hole.

A good diagram from gary shows the 90* angle rule and how it will affect trail and design. An example of using rule 2 would be gary's rude crude radiused rocker. By setting the rocker holes to zero unweighted, when the weight is applied then the springs automatically preload and set the proper angular relationship.

gary's diagram and the point marked PR is what we are trying to acheive, realize this chart is of the frontend in the weighted position

here is garys radiused rocker in the weighted position