Page 1 of 2

SPRINGER QUESTION

Posted: Sat Mar 08, 2014 11:37 pm

by hansgoudzwaard

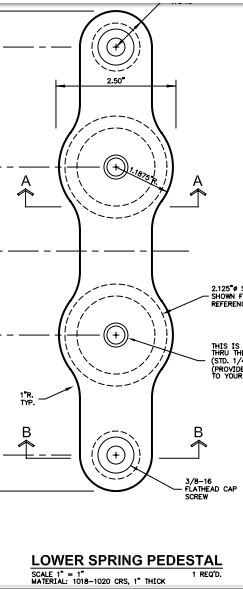

For Curt, Krymis, OR anyone building springers.

In the spring pedestal on Gary's plans, would it be OK to weld the front legs into section BB ?

I'm looking to simplify but want to keep it strong. I already have this style lower spring pedestal.

- WELD HERE

- SECBB.JPG (14.91 KiB) Viewed 6243 times

- DRILL THRU @ BB

- SECBB1.JPG (33.76 KiB) Viewed 6243 times

Re: SPRINGER QUESTION

Posted: Sun Mar 09, 2014 7:57 am

by Customize IT

I would not see a problem welding the pin to the fork tube would actually be stonger than that bolt designed there!

The only possible problem would be if over time that bearing surface of the pin was to become damaged there that you could not easy replace it like the bolted version?

Also if the pin is a hardened material welding it to the fork tube material would take a post and preheat process to not make the material crystalise during the welding process?

A tig welder would remove most of that process because of being able to control the heat better?

the main problem would be not being able to change that pin out if it was damaged over the life of the springer!

Re: SPRINGER QUESTION

Posted: Sun Mar 09, 2014 9:05 am

by krymis

in past when using 3/4" trees or thicker i have just bore a blind hole. top tree locks the tubes in place with out a pin or a bolt. now i make my springer so that the handlebar risers clamp the top tree in place. as for the front legs i always weld them in place.

Re: SPRINGER QUESTION

Posted: Sun Mar 09, 2014 10:37 am

by Customize IT

That pin he is talking about is for the rockers right?

You get a good welding procedure and you got no problems actually stronger!

Re: SPRINGER QUESTION

Posted: Sun Mar 09, 2014 4:01 pm

by hansgoudzwaard

Customize IT wrote:That pin he is talking about is for the rockers right?

You get a good welding procedure and you got no problems actually stronger!

Thanks for the good advice Guys.

It is the 2 areas on the attachment.

- weld it.

- SPRINGPERCH.JPG (93.72 KiB) Viewed 6227 times

Re: SPRINGER QUESTION

Posted: Mon Mar 10, 2014 2:14 pm

by gww25

I expected that virtually everybody would come up with their own unique bridge design. There is nothing wrong with making this a completely welded assembly (like they were originally in the old days). This is the least expensive part of the build so why not make several design alternates. I don't think I've ever built two the same anyway and most of the time I just use scrap for the bridge so the design can get pretty rudimentary.

Re: SPRINGER QUESTION

Posted: Mon Mar 10, 2014 2:37 pm

by gww25

Forgot to add that you can see how I typically build the bridge if you go back and look at the Springer Buildup article on the main site. It's pretty simple and a person can substitute solid stock where I was using 1x2x.120 tubing. I did the 'fancy' bridge design included with the plans only to show a 'modern' approach to the concept that let you save the bridge if you wanted to modify the leg length later on down the road when going from the sissy 35 degree rakes out to a nice 45 or more once 'chopper fear' was overcome.

Re: SPRINGER QUESTION

Posted: Mon Mar 10, 2014 3:27 pm

by hansgoudzwaard

gww25 wrote:Forgot to add that you can see how I typically build the bridge if you go back and look at the Springer Buildup article on the main site. It's pretty simple and a person can substitute solid stock where I was using 1x2x.120 tubing. I did the 'fancy' bridge design included with the plans only to show a 'modern' approach to the concept that let you save the bridge if you wanted to modify the leg length later on down the road when going from the sissy 35 degree rakes out to a nice 45 or more once 'chopper fear' was overcome.

I have re-read that article at least 5times. I like how you did the bridge there.

I had two complete sets of springer parts water-jetted, so they get used up first.

"Changing the rake" concept is great, that reasoning completely escaped me .

Thanks for the response. I appreciate it.

- Nice?

- HOHUM.JPG (76.67 KiB) Viewed 6212 times

Re: SPRINGER QUESTION

Posted: Sat Mar 22, 2014 9:07 pm

by hansgoudzwaard

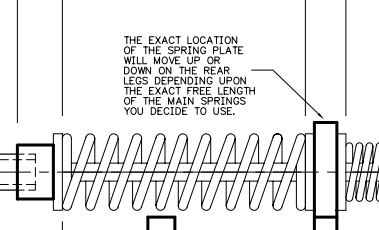

I am at making sure that I am familiar with the side notes and info on the springer drawings.

I am puzzled as to the importance of the drawing posted.

I understand that the true front leg length would be a result of spring length(one of the factors).

This note involves the neck, so I'm wondering how critical it is.

- stack height.JPG (59.3 KiB) Viewed 6191 times

In drawing SF1-3, we have a reference to the placement of the Spring Plate.

- SF1-3.JPG (28.57 KiB) Viewed 6191 times

Edit 22_14

The hole saws did not do the job. I thought I would try it, but these things are junk.

Paid to get the holes drilled, but did not read the note re. the reaming to get the fork tubes to slide in.

I took a coarse sanding belt, wrapped it around a piece of 1 inch tube, and smoothed out the hole so the rear legs would fit.

Works good.

- PartsMar21.JPG (38.14 KiB) Viewed 6185 times

Re: SPRINGER QUESTION

Posted: Mon Mar 24, 2014 7:30 pm

by kheaton

Will this be your build thread? I need the motivation.

Re: SPRINGER QUESTION

Posted: Mon Mar 24, 2014 7:48 pm

by hansgoudzwaard

kheaton wrote:Will this be your build thread? I need the motivation.

I don't know yet. I'm too sporadic at this up to this point.

If I say it's a build thread, then I am raising expectations.

I am going to pick away at the springer for the next month until it is useable, but not in paint or powder coat.

After that I may go back to work for a bit until the fall.

Re: SPRINGER QUESTION

Posted: Mon Mar 31, 2014 1:23 pm

by gww25

I'm surprised the hole saws didn't work out. I think maybe the reason might be that you used some 'good' steel for your trees. I think the saws are probably made of 4140 and you might have been sawing into some alloy that's a lot better that 1018/1020.

Yes the length of the neck can make a difference. You're running into the same problems I faced when trying to do a 'documentation' of building a springer and that is that there are dozens of variables involved, to many to really address in the typical Internet article. My intention was to provide a very 'broad' overview and unfortunately a lot of people took that as meaning that my way was the only way, which was not what I wanted. I think what really causes problems is that there really isn't such as thing as a 'standard' spring length. This has caused no end of problems for a lot of people who made the mistake of welding the perch in place before they bought springs. Anyway you're doing a great job and have thought through a lot of the typical problems so keep going.

Re: SPRINGER QUESTION

Posted: Mon Mar 31, 2014 3:34 pm

by gww25

I just re-read your bio Hans. 'Bonustoolkit'. You are indeed dedicated since you've been here from the start trying to support the site. Hope you get this buttoned up soon and move on to other matters.

Re: SPRINGER QUESTION

Posted: Wed Apr 02, 2014 11:43 pm

by hansgoudzwaard

gww25 wrote:I'm surprised the hole saws didn't work out. I think maybe the reason might be that you used some 'good' steel for your trees. I think the saws are probably made of 4140 and you might have been sawing into some alloy that's a lot better that 1018/1020.

Yes the length of the neck can make a difference. You're running into the same problems I faced when trying to do a 'documentation' of building a springer and that is that there are dozens of variables involved, to many to really address in the typical Internet article.

I had ordered these pieces after e-mailing the DXF files. The source is 100 miles from me across the strait, and they couriered them to me. Drilling, no biggy, I'm glad to have them. I will be passing by there by in a few months, and I'm going to take them an original piece to determine just what it is. So I'll know how to treat it next time.

The information you gave us is more than fine, it's a great guideline. These are not major problems, just orientation on my part.

I'm ordering springs, rods, etc. next.

Re: SPRINGER QUESTION

Posted: Wed Apr 02, 2014 11:51 pm

by hansgoudzwaard

gww25 wrote:I just re-read your bio Hans. 'Bonustoolkit'. You are indeed dedicated since you've been here from the start trying to support the site. Hope you get this buttoned up soon and move on to other matters.

Thanks for your replies.

I do like this site.

I am definitely going to carry through with what I started.

Creating these components with basic tools is a revelation(that's a strong word).

Makes you appreciate the complexity of the package and the importance of doing it right.