Page 2 of 4

Re: Irish's CBH CR200

Posted: Wed Jan 09, 2013 9:51 am

by Indian Mark

Hey Irish, What ever happened to the hot rod(s) you guys were building??

Re: Irish's CBH CR200

Posted: Wed Jan 09, 2013 1:15 pm

by IRISH

Hey you guys crack me up! I actually spent a week cleaning my shop up before starting this project! I found a bunch of misplaced tools and parts I forgot I had. Yeah I am not one to sit around watching to tube too much. I did check out the last chopper shows. It was American Chopper that got me going a few years back when it first started. I told myself if those two guys can do it then I sure can! The hot rod model A is still around Mark. It's down in NM at my Dads place. I went down a couple months ago and we pulled the Buick V6 out of his old 914 and mounted it up in the car. I'll post a pic soon. I will drag that car up here to Nor Cal this year if it last thing I do!

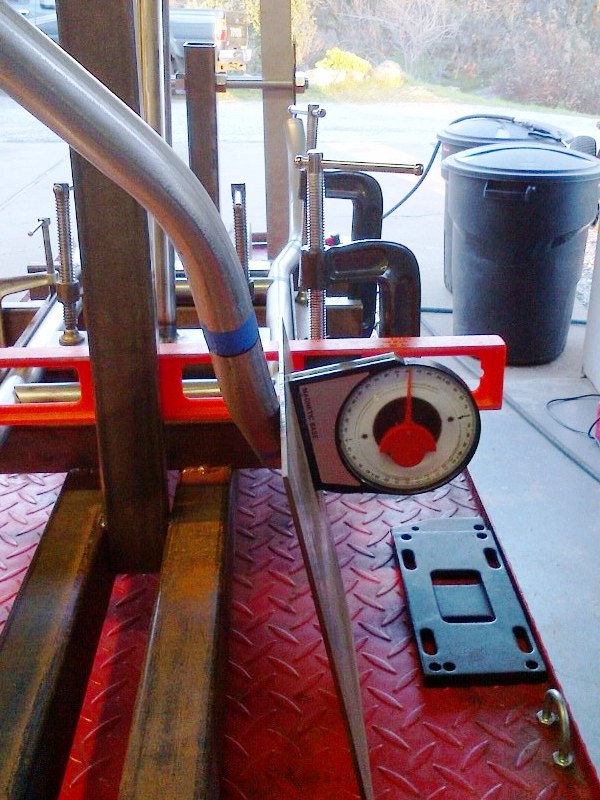

I am going to get bending the bottom tubes here soon. I need to make a plane of bend clamp for the angle gauge. I'm not paying 50 bucks for one. I think mechwerks has them for 30, but I can cut one out of some 1/2" material down at my brothers shop if I can just get over there and use his plasma cutter.

I found this idea on the web. It should work fine for the angle finder mount. I am going to but a new angle finder also as this one is crap.

- IMG-20130109-00929.jpg (44.33 KiB) Viewed 5586 times

- IMG-20130109-00930.jpg (51.12 KiB) Viewed 5586 times

- IMG-20130109-00931.jpg (80.38 KiB) Viewed 5586 times

Re: Irish's CBH CR200

Posted: Thu Jan 10, 2013 2:33 am

by IRISH

I got this wheel; an 80 spoke and AL hub. It was cheap, probably chinese I guess? I think its DNA.

Re: Irish's CBH CR200

Posted: Wed Jan 16, 2013 3:15 am

by IRISH

OK a little update. Unfortunately at this stage it doesn't look like much...I angled the neck fixture of the jig forward 20* and then adjusted the steering tube to 45* rake for this 43.5" long springer fork I want to use. I mocked it up with some yardsticks to check the height. I have the top frame tube stretched out another 3" from the plans that I am using, which are already 4" out from a '48 rigid pan frame. Looks like it should fit and look good at this angle...comments?

Looking at the third picture down, you can see that the wheel center is only 9.5 inches off the ground, the small silver sharpie line represents the ground, so that effectively raises my lower frame tubes up.

I know this means my lower rails will be about 4" higher than at the planned height of 5", but when all of the weight is put in, it should come down to it's planned ride height of around 4.5 - 5 inches. Maybe..I hope...

Also mocked up the handlebar riser height and looks like I will need a 12 - 14 inch tall bars to be able to reach them...The springer risers are 6" up from the top of the neck...

- neck fixture new.jpg (91.98 KiB) Viewed 5566 times

- neck fixture 45 deg.jpg (76.17 KiB) Viewed 5566 times

- fork mockup1.jpg (98.09 KiB) Viewed 5566 times

I know this means my lower rails will be about 4" higher, but with all of the weight put in it should come down to it's planned ride height of around 4.5 - 5 inches.

- fork mockup2.jpg (69.47 KiB) Viewed 5566 times

Also mocked up the handlebar riser height and looks like I will need a 12 - 14 inch tall bars to be able to reach them...

- riser mockup.jpg (98.79 KiB) Viewed 5566 times

Re: Irish's CBH CR200

Posted: Thu Jan 17, 2013 2:40 am

by IRISH

I printed a miter template for the top tube, cut it and set it back in the jig. The angle was supposed to be 45, but it turned out closer to 40 which is OK I think.

- IMG-20130116-00951.jpg (55.42 KiB) Viewed 5555 times

- IMG-20130116-00955.jpg (102.62 KiB) Viewed 5555 times

Re: Irish's CBH CR200

Posted: Sun Jan 20, 2013 2:23 am

by railroad bob

Nice work Craig, can't wait to see that long raked springer on the road.

Classic chopper style!!!

Re: Irish's CBH CR200

Posted: Sun Jan 20, 2013 2:35 pm

by IRISH

Thanks Bob! Yeah that springer is crazy long...I scored a 21" narrow hub front wheel, but the hub is still too wide for the brake rotor to fit.

- IMG-20130118-00957.jpg (114.92 KiB) Viewed 5533 times

I'm trying to get my head around how to bend the lower rails and it's giving me headaches! I'm using a single 1.5" down tube and I want it intersect the head tube near the bottom of the head tube. I'm attempting to use parts of two different plans from the CBH; the 200 and front down tube part from the 250-4, but without the radiused down tube. Complicated....I bent up some pieces of wire to try to visualize it. There are 5 bends and 3 rotations in each tube...I think.

- IMG-20130120-00963.jpg (74.2 KiB) Viewed 5533 times

I'll need to say a prayer and genuflect towards Texas for this one! Gary are you out there some where?

Re: Irish's CBH CR200

Posted: Sun Jan 20, 2013 8:26 pm

by curt

i dont know if this will help but i went through a similar problem what i did was spin up a couple slugs cut the tube where i was havin problems put in the slugs and played with a few short pieces till i could visualize it luckily i had lots of extra tube it took me a while

Re: Irish's CBH CR200

Posted: Sun Jan 20, 2013 8:47 pm

by IRISH

curt wrote:i dont know if this will help but i went through a similar problem what i did was spin up a couple slugs cut the tube where i was havin problems put in the slugs and played with a few short pieces till i could visualize it luckily i had lots of extra tube it took me a while

Yeah Curt that does help, I actually pm'd Gary and he suggested I do a mock up with some conduit or short tube bends and straights held together with hose clamps. these are both good ideas. I have some conduit so I'm going to go out and try it now. I'll let you know how it goes soon. Thanks!

Re: Irish's CBH CR200

Posted: Sat Jan 26, 2013 4:34 pm

by IRISH

I am having a hard time making this lower tube, especially the last bend that points the tube up and in to the axle plate.

The plans state: "This is a 32 degree up bend that puts the rear tube inward and upward at the same time. The rotation will be approximately 18 degrees depending on the bender"

My question is 18 degrees rotation from what reference point? I have tried this bend a half a dozen times with conduit following this instruction, but it doesn't come out right. Has anybody that is still around actually figured this out and done it? I have searched chopperweb and found numerous references to people trying to figure it out, but nobody has actually ever showed how to do it. I am using 1.25 tube and my bender radius is 4.5" just as called for in the plans.

I finally cut the tube after the last screw up and rotated the rear kick-up to align it properly. It seems that the 32 degrees as called for is too much. The angle of the rear tube where it goes up to the axle plate is supposed to end up at 25 degrees, but mine is at 30. It should be 25 degrees to match the angle of the top tubes.

- lower rail 1.jpg (119.97 KiB) Viewed 5501 times

- lower rail 2.jpg (109.37 KiB) Viewed 5501 times

- lower rail 3.jpg (108.84 KiB) Viewed 5501 times

- lower rail 4.jpg (111.39 KiB) Viewed 5501 times

Re: Irish's CBH CR200

Posted: Sat Jan 26, 2013 5:33 pm

by curt

ya i couldnt get that one either junked a bunch of tube ended up so fustrated i just did the first 40 deg bend then doing a 90 4and a half inches up back to the downtube actually liked the way it turned out

- 009.jpg (177.53 KiB) Viewed 5498 times

Re: Irish's CBH CR200

Posted: Sat Jan 26, 2013 5:46 pm

by curt

and i love that springer always liked those twisted legs

Re: Irish's CBH CR200

Posted: Sat Jan 26, 2013 11:07 pm

by IRISH

Curt, I think I got it. I bent a 28* angle (opened up from 32 a bit) and I made sure I had exactly 4" between the out bend and the up/in bend. Now my rear tube angle is 25* like it's supposed to be. I know this is why Gary states numerous times that everyone's work will be different and practice is important! I now have a pattern in 1" EMT. Now if i can just copy it to the tubing I'll be good. I still don't know how many degrees to rotate exactly, or from where, but I'm getting there!

I read on chopperweb how JJ does it, bend out then rotate 180 and bend back in and then up to the axle plate, which is what you did Curt. But I want this fucker to match the plans and be symmetrical top to bottom. I also modified the axle plate fixture on the jig to match the dims from the plans exactly.

- 10deg.jpg (139.77 KiB) Viewed 5474 times

- 25deg.jpg (103.64 KiB) Viewed 5474 times

Re: Irish's CBH CR200

Posted: Mon Feb 04, 2013 4:12 am

by IRISH

OK, I finally figured out the best way to bend these lower rails on the 200. Here's how: Start at the rear and measure out 15" and mark the tube. I found a piece of material that fits snug over the tube so I can make a line around the tube. Make the first bend, which I figured out on my bender should be 28 degrees (as opposed to the 32 called for in the plans). Lay the tube on a table and set the angle up with a protractor so it's at the desired 25*. Look at the pictures I took that shows the setup. Then mark the tube in the center or 5/8" up from the table. This will be the center line of the out bend.

- setup1.jpg (173.53 KiB) Viewed 5455 times

- setup2.jpg (134.94 KiB) Viewed 5455 times

If you are using 1.25" OD tube as I am, then you can divide the tube circumference into degrees pretty easily. The diameter is very close to 4" so 90* = 1", and 10* = 1/8". even though this is not exact it will work fine for this and it's easier than trying to clamp the protractor to the tube when its in the bender. You can double check it with the protractor also.

So, the distance around the tube from the "up" bend to the "out" bend turns out to be 90* + .25" (1/4"). Using a flexible tape you can measure around the tube and mark it. I am using the center line of the inside radius of the bends to measure from, as that is the easiest for me to visualize.

- setup3.jpg (165.96 KiB) Viewed 5455 times

- setup4.jpg (119.35 KiB) Viewed 5455 times

From trial and error using the 1"EMT I figured out I needed a bit more than the 12* as specified in the plans so I went with 13* mark on my bender gauge. I measured 4" from the end of the first bend, this is where the out bend starts. Then make the out bend. You can check that the bends are correct by laying the tube back on the table and clamping a plate to the edge of the table then setting the tube up against the plate and aligning the tube with the edge of the table and measuring from the edge of the table to the tube. The tube should be parallel with the edge of the table.

Re: Irish's CBH CR200

Posted: Mon Feb 04, 2013 4:43 am

by IRISH