Page 3 of 8

Re: Dusty's Bonneville Scout Build

Posted: Mon Mar 07, 2016 1:53 pm

by Dusty-Dave

My wife has been in the hospital since the last of Jan. So I hav made 0 progress except for a few parts and Tig welder from the www. Funfool if you are still around check your messages I'm in Albuquerque untill she gets out.

Dusty

Re: Dusty's Bonneville Scout Build

Posted: Sun Oct 02, 2016 1:04 am

by Dusty-Dave

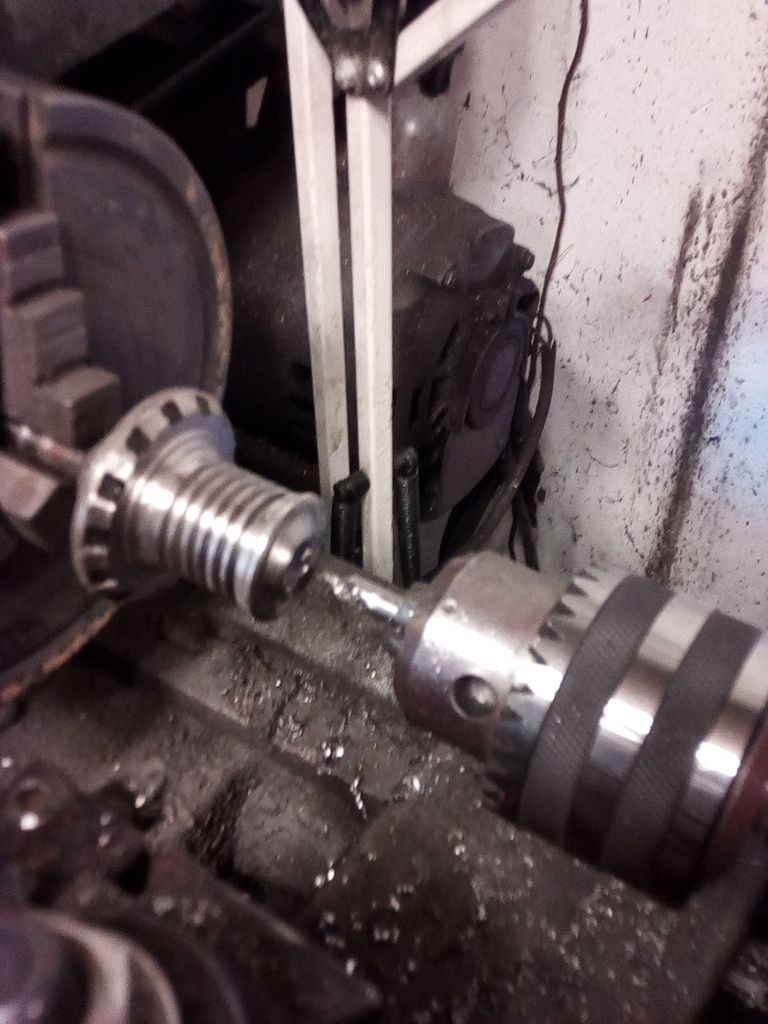

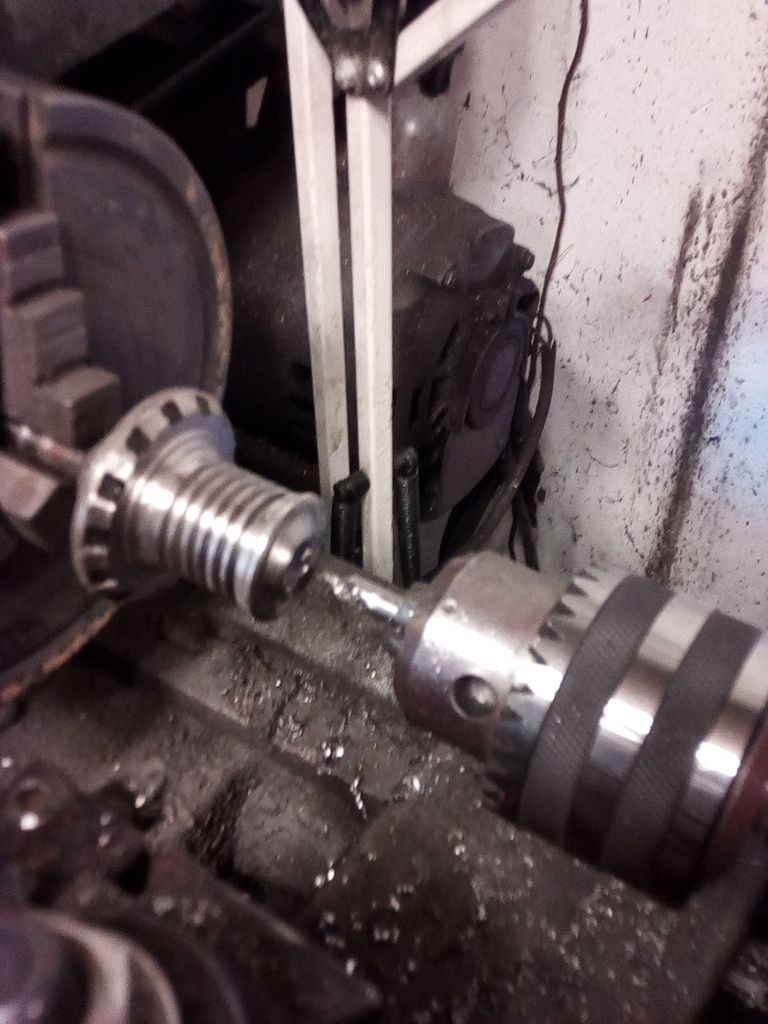

Cuz there are so many around that need rebuilt n I got this one for free, I decided to turn the Garrett variable vane turbo from a Ford 6.0 Diesel into a belt driven centrifugal supercharger.

I decided to cut the exhaust turbine down into a serpentine pulley instead of making a new shaft and pulley from scratch. Hardest stuff I've ever seen! I turned the vanes off with cemented carbide running about 36 rpm and still had to stop at half cut and resharpen the carbide. Once the vanes were gone I broke out the diamond grinding wheel on the tool post grinder.

Almost small enough to start cutting little bitty Vs

I don't have enough spare oil to take care of the bushings and the engine so it is going to get a pair of sealed ceramic bearings rated for 60,000 rpm. .

Probably should have junked the turbine n shaft but I can be a trifle bit hard headed once I decide what way to do something.

Dusty

Re: Dusty's Bonneville Scout Build

Posted: Tue Oct 04, 2016 1:40 am

by Dusty-Dave

I priced the inserts to cut the serpentine grooves. I've always ground them out of tool steel which won't even touch this exhaust turbine. At $300+ I got out my diamond files and hand filed one out of carbide. Will try it out tomorrow, whisky n pills sounds better than working this late.

All the measurements of the common automotive serpentine belts.

Dusty

Re: Dusty's Bonneville Scout Build

Posted: Wed Oct 12, 2016 10:31 pm

by Dusty-Dave

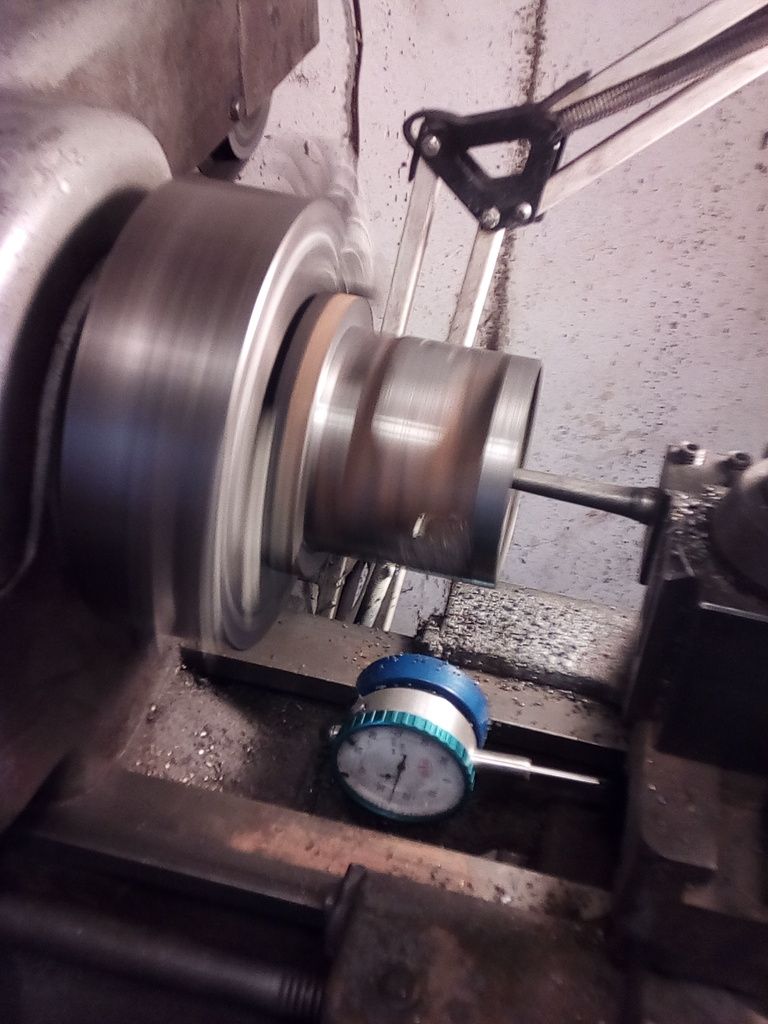

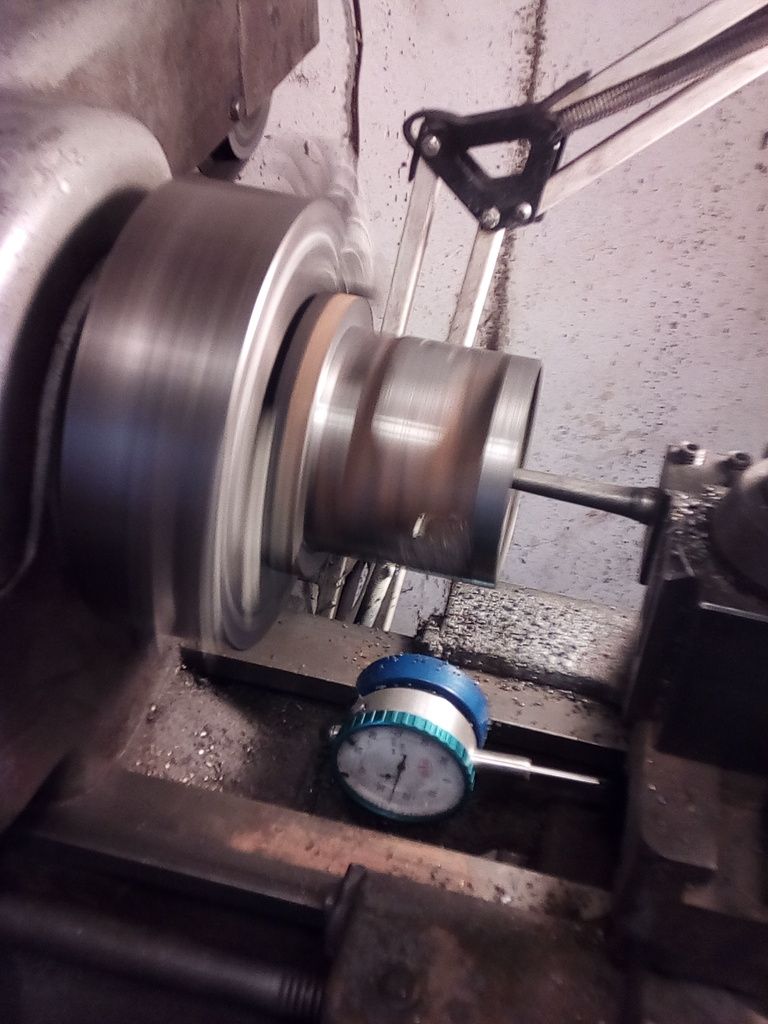

Finished the pulley today. Still waiting on the bearings so the shaft is still waiting. Next one I will turn the turbine smooth and shrink some aluminum tube on to make the pulley from, but I had to see if I could do it.

Dusty

Re: Dusty's Bonneville Scout Build

Posted: Thu Oct 13, 2016 4:21 am

by gearhead1951

I hope you intend to use an outrigger bearing ! The side load from the belt could prove to be more than the center bearing of that turbo can handle !

Re: Dusty's Bonneville Scout Build

Posted: Thu Oct 13, 2016 10:10 am

by Dusty-Dave

That kinda stuff is why I'm testing. If it was a street bike it would absolutely get a outboard bearing. But to run 5 miles at a time if the ceramic bearings can stand the strain for 3 or four runs a day for a week saving 3 or 4 pounds is real important. The diameter of the pulley is too small but if I can get a high enough gear ratio for enough boost without a jack shaft there is another 4 or 5 pounds. And I can only diet so much, they ( can't remember who they are) say that on a unfaired bike ten pounds is about the same as 1 horsepower.

Dusty

Re: Dusty's Bonneville Scout Build

Posted: Tue Oct 18, 2016 9:09 pm

by Dusty-Dave

Started puttin it on a diet today. Unbolted, cutoff wheel, grinder, hacksaw n hammer got somewhere around 20 lbs off.

Dusty

Re: Dusty's Bonneville Scout Build

Posted: Wed Oct 19, 2016 4:49 am

by gearhead1951

Even for short runs , if the impeller touches the inside of the compressor because the stock bearing caint handle the side load the resulting destruction will be monumental !

Re: Dusty's Bonneville Scout Build

Posted: Wed Oct 19, 2016 4:21 pm

by Dusty-Dave

Changing to ceramic ball bearings don't want to spare any engine oil for the bushing which was toast anyway. After looking at the specs for the bearings I ordered I think I'm gonna run 2 on the belt side. I met a guy at Bonneville that had a similar setup on a triumph that he had been racing for years. He was using V Belts, a jackshaft and regular steel sealed bearings with grease zerks. So hopefully the ceramics running in light oil and the serpentine at lower tension should do it. This is a much larger impeller so I should be able to turn it slower. We'll see. If I have to use an outboard bearing I will machine shaft and pulley as one piece from 4130 or so. Having way more contact than I wanted with Jimmy 2 stroke diesels over the years I'm quite familiar with what a top end looks like after a turbo explosion and would prefer to avoid it.

Dusty

Re: Dusty's Bonneville Scout Build

Posted: Thu Oct 20, 2016 4:45 am

by gearhead1951

20 years in the US Navy as a main propulsion diesel engineer working on those same BIG 2 stroke "jimmies" ! Some with a turbo feeding the supercharger !

Re: Dusty's Bonneville Scout Build

Posted: Thu Oct 20, 2016 1:01 pm

by Dusty-Dave

That's the ones I'm talkin about you probably never had the problem in the military but cheap assed contractors n owner operators would let the air filter get dirty enough that the intake restriction and the roots evacuating air as long as it runs. The turbos would over speed in the rarefied air until the impellers exploded like a bomb. Quite a devastating event but ever now and then some one needed to learn about preventive maintenance I suppose.

Dusty

Re: Dusty's Bonneville Scout Build

Posted: Fri Oct 21, 2016 4:31 am

by gearhead1951

You must be referring to the "71" series ! The engines I worked on were 248 to 268 cid per cylinder ! And you are absolutely right , I caught a "trucker" taking his air cleaner off and flipping the filter before reinstalling it thinking that he was being "thrifty" by getting more miles on one filter ! You should have seen his face when I finally got him to understand where all that dirt the filter had stopped was going now that he had reversed the flow thru it !!;)

Re: Dusty's Bonneville Scout Build

Posted: Fri Oct 21, 2016 11:31 am

by Dusty-Dave

71 & 92s inline & v were prone to turbo explosions I never worked on anything Deathroit over 16V71 but I suppose that anything with a roots and a turbo could have that problem.

Dusty

Re: Dusty's Bonneville Scout Build

Posted: Sun Nov 13, 2016 12:01 am

by Dusty-Dave

Started smoothing and rounding all the points and flat spots the hand grinder with a cutoff wheel left.

Dusty

Re: Dusty's Bonneville Scout Build

Posted: Thu Nov 17, 2016 3:31 pm

by Dusty-Dave

Got the outside round enough for the band clamp I plan to mount it with. So on to the boring part or is that boring the part?

The bore is now 22mm for the ceramic bearings.

Dusty